|

Daeyong Industry has produced high-pressure Al die-casting for automotive parts and has achieved outstanding growth with strict quality control and excellent engineering since its establishment in 1983. Daeyong Industry has been recognized by global customers for its superior technology.

Daeyong Industry has established itself as a global company by producing and supplying automotive parts to clients all over the world such as North America (GM, DELPHI, NSK, HITACHI, EATON, ALLISON, etc), Europe (BORGWARNER, VALEO, etc), South America (GM, DELPHI), and Asia (NSK, WABCO KOREA, etc). The company’s sales are export-oriented with 90% from the automotive industry alone.

Last year, Daeyong Industry won the ‘Supplier of the Year’ award by GM for its efforts to satisfy customer demands. Its customers require an ever increasing standard of higher quality and more complete structure with lower cost. Following this trend, DaeYong Industry is focusing on the growth of R&D and Quality capabilities and has also achieved certifications such as IATF 16949, ISO 14000, and ISO 45001.

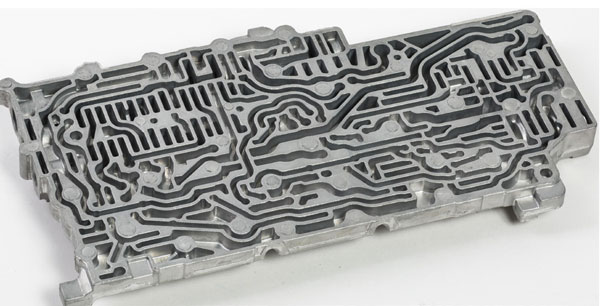

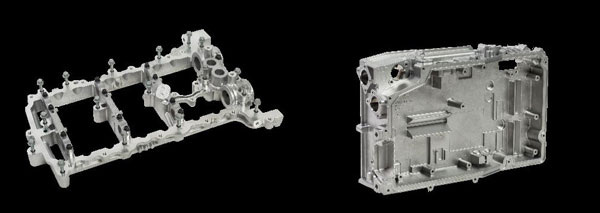

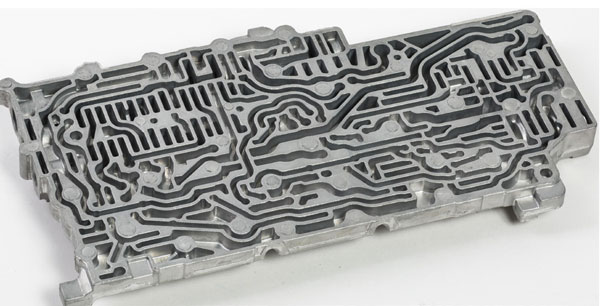

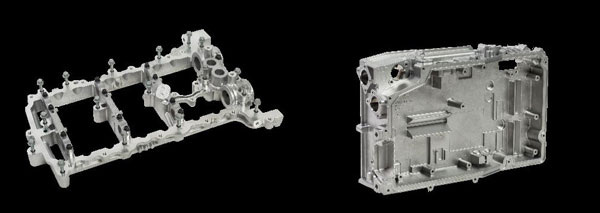

Its products include engine parts (Cam carrier, Cam-cap, Throttle body, EGR), Transmission parts (Valve body, Solenoid valve), Steering parts, Inverter for EV, and valve body, cam-cap ASM, throttle body, steering parts, and Inverter for EV.

Valve bodies are directly supplied to GM, Borgwarner, Eaton, and Allison. The process consists of super high speed die-casting, and machining and customer requirements are inner porosity, particle, leak, anodizing, tight machining requirement or customer machining. Daeyong Industry has achieved quality score of valve body casting as 0PPM, based on Y2015~Y2018.

Cam carrier is directly supplied to GM. The process consisting of super high speed die-casting, machining, and sub-assembly and requirement includes bolting, particle, leak, mechanical property.

Inverters for EVs are directly supplied to Delphi Technologies, and Hitachi Automotive. The process consists of super high speed, high pressure die casting, machining, and sub assembly and customer requirements are for cleanliness spec- particle size, leak requirement, thin-wall, and light weight.

With these products, Daeyong Industry has gained recognition for its superior technology from numerous customers, and has been constantly growing as a reliable company offering high quality, reasonable price and delivery compliance to even exceed customer satisfaction.

[SOURCES] korean-machinery.com

|